The manufacturing sector in India plays a crucial role in economic growth, employment generation, and industrial development. From textiles and automobiles to pharmaceuticals and electronics, manufacturing drives exports, innovation, and domestic consumption. However, the sector faces significant supply chain challenges that affect efficiency, costs, and competitiveness. Complex logistics networks, fragmented suppliers, rising input costs, and regulatory hurdles create bottlenecks that disrupt production and delay deliveries. The COVID-19 pandemic further highlighted vulnerabilities in global and domestic supply chains, forcing manufacturers to rethink strategies and adopt more resilient models. This article examines the key supply chain challenges in Indian manufacturing, their impact on operations, and potential strategies to overcome them.

Importance of Supply Chain Management in Manufacturing

Supply chain management (SCM) involves planning, sourcing, production, logistics, and distribution of goods from suppliers to end customers. Efficient SCM ensures timely availability of raw materials, optimized inventory, cost reduction, and high-quality output. In the competitive global market, a robust supply chain is critical for meeting customer expectations, reducing operational risks, and maintaining profitability.

In India, manufacturing accounts for nearly 17% of GDP and provides employment to millions. Disruptions in supply chains can directly impact production timelines, export competitiveness, and revenue generation. Therefore, addressing supply chain challenges is vital for sustaining growth and positioning India as a global manufacturing hub under initiatives like “Make in India.”

Key Supply Chain Challenges in Indian Manufacturing

1. Fragmented Supplier Base

Indian manufacturers often rely on a large number of small and medium suppliers for raw materials, components, and services. This fragmentation creates difficulties in coordination, quality control, and timely delivery.

- Impact: Inconsistent supply, variable quality, and delays in production schedules.

- Example: Automotive manufacturers sourcing components from multiple small vendors may face production halts due to delays from a single supplier.

2. Logistics and Infrastructure Constraints

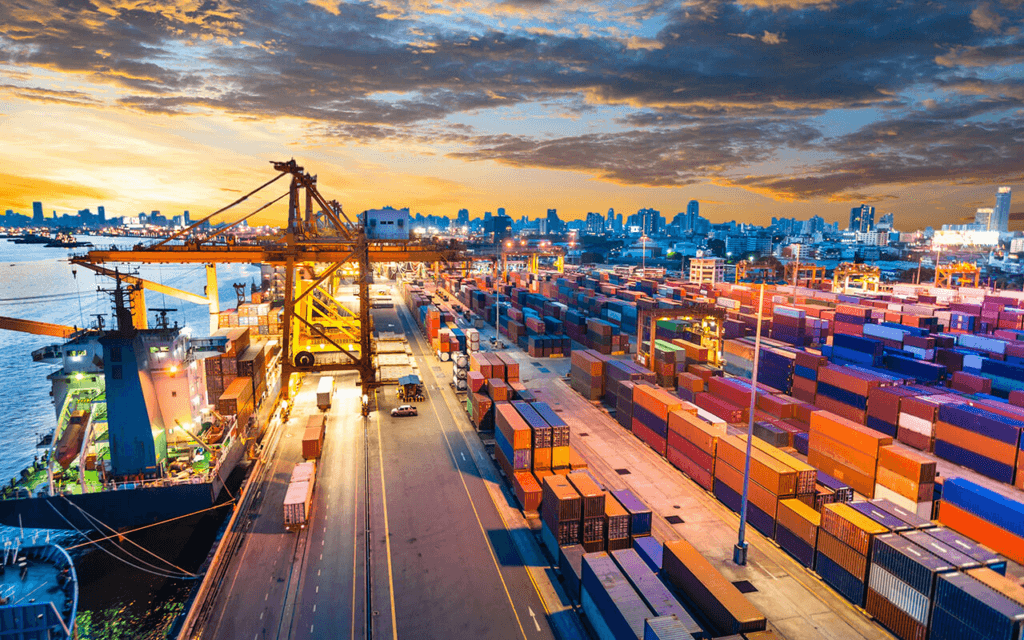

India’s logistics network faces challenges such as inadequate road and rail connectivity, congestion at ports, and inefficient warehousing facilities. Transportation inefficiencies increase lead times, elevate costs, and limit the ability to meet customer demands promptly.

- Impact: Higher logistics costs, delayed deliveries, and reduced competitiveness in global markets.

- Example: Export-oriented textile units in Tamil Nadu or Gujarat may experience shipment delays due to port congestion and poor last-mile connectivity.

3. Inventory Management Issues

Many manufacturers struggle with balancing inventory levels, leading to overstocking or stockouts. Overstocking ties up capital, increases storage costs, and risks obsolescence. Stockouts, on the other hand, disrupt production and affect customer satisfaction.

- Impact: Inefficient use of working capital, production delays, and missed market opportunities.

- Example: Electronics manufacturers relying on imported components may face stockouts if imports are delayed, affecting production schedules.

4. Volatile Raw Material Prices

Price fluctuations in raw materials such as steel, plastic, chemicals, and cotton pose a significant challenge. Factors like global market trends, trade policies, and currency fluctuations directly affect procurement costs.

- Impact: Increased production costs, margin pressures, and pricing uncertainty.

- Example: Steel-dependent industries such as automotive and construction face cost escalations during periods of international price surges.

5. Regulatory and Compliance Challenges

India’s regulatory environment, including taxation, labor laws, and environmental regulations, can complicate supply chain operations. Compliance requirements, paperwork, and inspections often lead to delays and increased administrative costs.

- Impact: Slower production cycles, higher operational expenses, and risk of penalties.

- Example: Manufacturing units in multiple states must navigate different GST rules and labor compliance requirements, adding complexity to supply chains.

6. Technology and Digitalization Gaps

Despite the growing adoption of Industry 4.0 technologies, many Indian manufacturers lag in integrating digital tools for supply chain management. Limited use of AI, IoT, predictive analytics, and ERP systems reduces visibility, responsiveness, and efficiency.

- Impact: Poor demand forecasting, inefficient production planning, and delayed response to market changes.

- Example: Small-scale manufacturers often rely on manual inventory management, leading to errors and missed opportunities.

7. Skilled Workforce Shortage

Effective supply chain management requires trained professionals who can handle procurement, logistics, planning, and technology adoption. However, India faces a shortage of skilled supply chain managers, logistics experts, and data analysts.

- Impact: Operational inefficiencies, mismanagement of resources, and slower adoption of best practices.

- Example: Improper inventory planning due to lack of skilled personnel can result in overproduction or shortages.

8. Global Supply Chain Dependencies

Many Indian manufacturers rely on imports for raw materials, components, and advanced machinery. Global disruptions, such as geopolitical tensions, trade restrictions, and pandemics, can severely impact supply chains.

- Impact: Delays, cost increases, and production stoppages.

- Example: Electronics and pharmaceutical manufacturers importing critical components from China experienced supply disruptions during the COVID-19 pandemic.

Strategies to Overcome Supply Chain Challenges

Addressing supply chain challenges requires a combination of technology, policy support, and operational strategies.

1. Supplier Consolidation and Collaboration

Developing strong relationships with reliable suppliers and consolidating procurement can reduce variability and improve quality. Collaborative planning, regular audits, and performance-based contracts enhance supplier reliability.

2. Investment in Logistics Infrastructure

Improving warehousing, transportation networks, and last-mile delivery solutions reduces lead times and costs. Public-private partnerships (PPP) and initiatives like Bharatmala and Sagarmala aim to strengthen India’s logistics infrastructure.

3. Advanced Inventory Management

Using predictive analytics, demand forecasting, and ERP systems helps optimize inventory levels. Manufacturers can reduce overstocking, avoid stockouts, and improve cash flow management.

4. Hedging Against Price Volatility

Manufacturers can adopt procurement strategies such as bulk buying, futures contracts, and supplier agreements to mitigate raw material price fluctuations. This approach ensures cost stability and predictable margins.

5. Regulatory Streamlining and Compliance Automation

Leveraging technology to manage compliance and standardizing procedures across states can minimize delays. Automation of tax filings, documentation, and inspections reduces administrative burdens.

6. Technology Adoption and Digital Transformation

Implementing AI, IoT, robotics, and blockchain can enhance supply chain visibility, improve production planning, and enable real-time tracking. Digital platforms also facilitate better communication with suppliers, distributors, and customers.

7. Workforce Training and Skill Development

Investing in supply chain education, vocational training, and skill development programs helps create a competent workforce capable of managing modern supply chains efficiently.

8. Diversification and Localization

Reducing dependence on global suppliers by developing local sources and diversifying procurement mitigates risk. Initiatives like “Atmanirbhar Bharat” encourage domestic production of key components, enhancing supply chain resilience.

Future Outlook

The future of supply chain management in Indian manufacturing is likely to be shaped by technology, policy reforms, and sustainability trends. AI-driven predictive analytics, autonomous logistics, and smart warehouses will improve efficiency and reduce disruptions. Government initiatives to modernize infrastructure, simplify regulations, and promote local sourcing will further strengthen supply chains. Sustainability will also become a key consideration, with manufacturers adopting green logistics, energy-efficient practices, and eco-friendly materials.

By addressing supply chain challenges proactively, Indian manufacturers can enhance competitiveness, reduce costs, improve customer satisfaction, and contribute to the country’s economic growth. Robust supply chains will also position India as a reliable global manufacturing hub, attracting investment and boosting exports.

Conclusion

Supply chain challenges in Indian manufacturing are multifaceted, ranging from fragmented suppliers, logistics inefficiencies, and raw material volatility to regulatory complexities, technology gaps, and skilled workforce shortages. These challenges directly impact production, costs, and competitiveness.

However, with strategic interventions such as supplier consolidation, digitalization, infrastructure investment, regulatory simplification, and workforce training, manufacturers can overcome these obstacles. Diversification of supply sources and adoption of sustainable practices further enhance resilience. Strengthening supply chains will not only improve operational efficiency but also support India’s vision of becoming a global manufacturing leader under initiatives like “Make in India” and “Atmanirbhar Bharat.”

By embracing innovation, technology, and collaborative strategies, Indian manufacturers can build supply chains that are agile, efficient, and capable of withstanding domestic and global disruptions. This will ensure sustained growth, competitiveness, and a stronger position in the international market.

FAQs

- What are the main supply chain challenges in Indian manufacturing?

Challenges include fragmented suppliers, logistics inefficiencies, inventory mismanagement, volatile raw material prices, regulatory hurdles, technology gaps, skilled workforce shortage, and dependence on global suppliers. - How does poor logistics affect manufacturing in India?

Inefficient transportation, congested ports, and inadequate warehousing increase costs, delay deliveries, and reduce competitiveness. - What strategies can manufacturers adopt to improve supply chains?

Strategies include supplier consolidation, investment in logistics infrastructure, digital transformation, predictive inventory management, workforce training, regulatory compliance automation, and sourcing diversification. - How will AI and technology shape the future of supply chains in India?

AI, IoT, predictive analytics, and smart logistics will improve visibility, efficiency, and responsiveness, enabling manufacturers to handle disruptions and meet global standards.

Next Topic: Oil Imports and India’s Energy Security

Also Check: AI Applications in Indian Healthcare Sector