India’s electronics manufacturing sector has been experiencing a significant boom, emerging as one of the most dynamic segments of the country’s industrial landscape. This growth is driven by domestic demand for electronic goods, government initiatives to promote manufacturing, global supply chain diversification, and increasing foreign investments. From smartphones and consumer electronics to semiconductors, industrial electronics, and electronic components, India is rapidly positioning itself as a major hub for electronics production in Asia.

The electronics manufacturing boom is closely tied to India’s broader economic and technological ambitions. It aligns with government programs like “Make in India,” Production-Linked Incentive (PLI) schemes, and Digital India, all aimed at strengthening domestic manufacturing capabilities, creating jobs, and reducing import dependence. Furthermore, the global push for diversification of electronics supply chains, particularly in the wake of disruptions during the COVID-19 pandemic, has made India an attractive destination for investment.

Understanding the electronics manufacturing boom in India requires exploring the sector’s growth drivers, investment trends, government policies, challenges, and future prospects.

Growth Drivers of Electronics Manufacturing in India

1. Rising Domestic Demand

India’s domestic market for electronics has grown exponentially, fueled by rising income levels, urbanization, and changing consumer behavior. Smartphones, laptops, tablets, televisions, smart home devices, and wearable technology are in increasing demand across urban and semi-urban areas.

The demand is not limited to consumer electronics. Industrial electronics, automation equipment, telecom infrastructure, and defense electronics also contribute to the market’s expansion. As more sectors adopt digital solutions and automation, the need for domestically produced electronic components has surged.

2. Government Initiatives

Government support has played a crucial role in catalyzing India’s electronics manufacturing sector. Key initiatives include:

- Make in India: Launched in 2014, this program aims to boost domestic manufacturing across sectors, including electronics.

- Production-Linked Incentive (PLI) Scheme: Introduced for electronics manufacturing, semiconductors, and telecom equipment, the PLI scheme incentivizes companies to scale production in India through financial support linked to output.

- Electronics Manufacturing Clusters (EMCs): The government has established EMCs to provide world-class infrastructure, reduce operational costs, and promote manufacturing excellence.

- Digital India: This initiative promotes technology adoption and drives demand for digital devices, creating opportunities for electronics manufacturers.

These initiatives encourage both domestic and foreign companies to invest in manufacturing facilities, R&D centers, and supply chain infrastructure.

3. Foreign Direct Investment (FDI) and Global Supply Chain Shifts

India has become an attractive destination for foreign investment in electronics manufacturing. Policy reforms allowing 100% FDI in electronics manufacturing and related sectors have attracted global players such as Foxconn, Samsung, Xiaomi, and Pegatron.

Global supply chain diversification, accelerated by the COVID-19 pandemic and geopolitical tensions, has prompted multinational companies to reduce reliance on China and explore alternative manufacturing bases. India’s competitive labor costs, large domestic market, and supportive policies make it a viable option for electronics production and assembly.

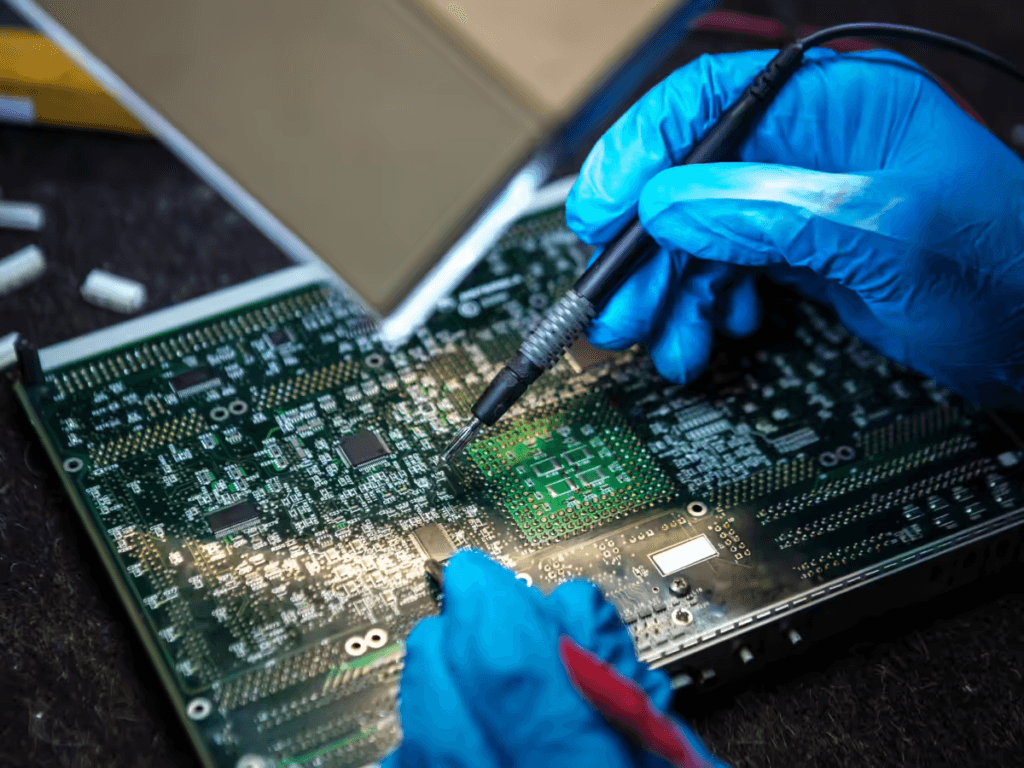

4. Technological Advancements and Innovation

Advancements in semiconductor technology, automation, robotics, and digital design tools have improved the efficiency and scalability of electronics manufacturing. Indian manufacturers are increasingly adopting modern production techniques, smart factories, and AI-enabled quality control, enhancing competitiveness and product quality.

Startups and innovation hubs focused on electronics components, IoT devices, and wearable technology are also contributing to the sector’s growth, promoting indigenous design and intellectual property development.

Investment Trends in Electronics Manufacturing

1. Large-Scale Manufacturing Facilities

Several global and Indian companies are establishing large-scale manufacturing units in India. Smartphone assembly plants, semiconductor fabrication units, consumer electronics factories, and PCB manufacturing facilities are expanding rapidly.

For instance, leading smartphone manufacturers such as Samsung, Xiaomi, and Vivo have invested heavily in assembly plants across Tamil Nadu, Karnataka, and Andhra Pradesh. These investments not only serve the domestic market but also enable exports to international markets.

2. Semiconductor and Chip Manufacturing

Semiconductors are a critical component of electronic devices, and India has identified chip manufacturing as a strategic priority. While domestic semiconductor fabrication is still nascent, the government’s PLI scheme and incentives for semiconductor design and assembly are attracting major players to establish fabrication units and R&D centers.

Developing domestic semiconductor capabilities is vital for reducing import dependence, enhancing supply chain resilience, and supporting the growing electronics ecosystem.

3. Component and Ancillary Manufacturing

India’s electronics manufacturing boom extends beyond end products to components such as printed circuit boards (PCBs), connectors, sensors, and displays. Investment in ancillary units ensures the creation of an integrated supply chain, reduces import reliance, and strengthens the ecosystem for future growth.

4. Startups and Innovation Hubs

The electronics manufacturing landscape is also benefiting from startups developing innovative devices, IoT solutions, and automation equipment. Government-supported innovation hubs and incubators promote research, prototype development, and collaboration with larger manufacturers, fostering a culture of innovation and self-reliance in electronics.

Challenges in Electronics Manufacturing

Despite strong growth, the sector faces several challenges that could affect sustainability and competitiveness:

1. Supply Chain Dependence

India remains dependent on imports for critical components such as semiconductors, advanced chips, and certain raw materials. Developing domestic production capabilities for these inputs is essential to achieve self-reliance and reduce vulnerability to global supply chain disruptions.

2. Infrastructure and Logistics Constraints

While government initiatives have improved infrastructure, manufacturing still faces challenges related to power supply, transportation networks, port facilities, and logistics efficiency. High-quality infrastructure is essential for attracting large-scale investments and ensuring competitive production costs.

3. Skill Shortages

Electronics manufacturing requires skilled labor for design, assembly, testing, and quality control. India faces a shortage of specialized technicians and engineers with expertise in advanced manufacturing and semiconductor technologies, limiting the sector’s growth potential.

4. Regulatory and Policy Challenges

Although India has implemented supportive policies, navigating regulatory approvals, taxation, and compliance requirements can be complex. Consistency in policies, ease of doing business, and clear guidelines for investment are critical for long-term growth.

5. High Capital Expenditure

Setting up electronics manufacturing units, especially semiconductor fabrication plants, involves significant capital investment. This can deter small and medium enterprises from entering the sector, concentrating production among a few large players.

Future Outlook of Electronics Manufacturing in India

The electronics manufacturing sector in India is poised for continued growth, driven by domestic demand, global investments, and supportive government policies. Key trends likely to shape the sector include:

- Expansion of Semiconductor Manufacturing: India aims to develop semiconductor fabrication and design capabilities, reducing import dependence and fostering high-value manufacturing.

- Focus on Exports: With the PLI scheme and competitive manufacturing capabilities, India is increasingly positioning itself as an export hub for smartphones, consumer electronics, and industrial devices.

- Integration with Digital Economy: The growth of IoT, 5G infrastructure, AI-enabled devices, and smart manufacturing will further stimulate electronics production.

- Sustainable Manufacturing: Adoption of green manufacturing practices, energy-efficient factories, and recycling initiatives will be important for long-term sustainability.

- Startups and Innovation Ecosystem: Startups focusing on components, robotics, automation, and electronic devices will continue to drive innovation, complementing large-scale manufacturing.

With strategic investments, technological adoption, and policy support, India has the potential to become a global electronics manufacturing hub, creating jobs, boosting exports, and reducing reliance on imports.

Conclusion / Final Thoughts

India’s electronics manufacturing boom represents a critical opportunity for economic growth, technological advancement, and global competitiveness. Rising domestic demand, supportive government initiatives, foreign investment, and technological innovation have created a conducive environment for electronics production across consumer, industrial, and defense segments.

The sector’s growth is driven by smartphones, consumer electronics, semiconductors, industrial electronics, and components manufacturing. Government initiatives such as Make in India, PLI schemes, Electronics Manufacturing Clusters, and Digital India have accelerated investment and expanded manufacturing capabilities. At the same time, global supply chain diversification has positioned India as an attractive alternative for multinational companies seeking stable, cost-effective production bases.

Challenges such as supply chain dependence, infrastructure gaps, skill shortages, regulatory complexities, and high capital requirements remain, but strategic planning, investment in technology and infrastructure, and skill development can address these hurdles.

The future of electronics manufacturing in India is promising, with opportunities in semiconductor production, export-oriented manufacturing, digital economy integration, sustainable practices, and innovation-led startups. By leveraging these trends, India can strengthen its position as a leading electronics manufacturing hub, supporting domestic consumption, boosting exports, and contributing to long-term economic growth.

FAQs

1. What is driving the electronics manufacturing boom in India?

The boom is driven by rising domestic demand, government initiatives like Make in India and PLI schemes, foreign direct investment, technological innovation, and global supply chain diversification.

2. Which segments are growing the fastest in India’s electronics manufacturing?

Smartphones, consumer electronics, industrial electronics, semiconductors, and electronic components are experiencing the fastest growth.

3. What are the main challenges facing electronics manufacturing in India?

Challenges include supply chain dependence, infrastructure and logistics constraints, skill shortages, regulatory complexities, and high capital expenditure requirements.

4. What is the future outlook for electronics manufacturing in India?

The sector is expected to grow with semiconductor manufacturing, export-oriented production, integration with the digital economy, sustainable practices, and innovation-led startups, positioning India as a global electronics hub.

Next Topic: Government Policies Affecting Oil and Gas Industry in India

Also Check: Telemedicine in India: Market Size and Challenges